Vibratory Sifter is used in Sifting of materials in Pharmaceutical manufacturing with different mesh of Sieves and it is widely used equipment in pharmaceuticals and in food industries.

Uses of Vibratory Sifter :

Sifting is done to remove lumps or growth that might have formed on the materials after being stored for a longer period and materials are passed through a mesh that opens, which leads to fine the materials. It also removes the unrequired foreign particles and separate the materials according to size

Types of Vibratory Sifter :

- One layer, Vibro sifter.

- Double layer Vibro sifter, which has two layers.

- Triple-layer Vibro sifter that has three layers.

- Industrial Vibro sifter which is commonly used in food processing industries.

- L-shaped sieve frame Vibro sifter.

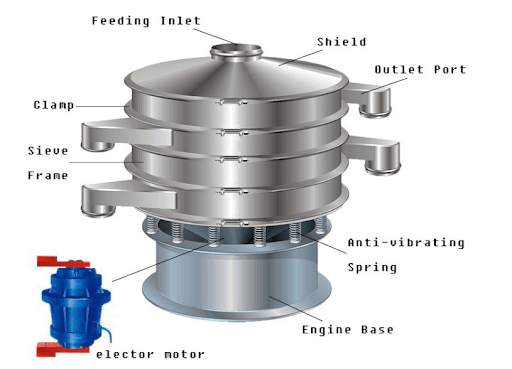

Different parts of Vibratory Sifter :

Hopper Lid :

Hopper lid is made from metal and this is also called a cover lid.

This component covers the ingredients being processed on the upper section of the machine and it prevents them from falling off whenever the machine is vibrating.

It also helps in preventing the materials from contamination and dusting and it is held up on to the device by a clamping ring.

Filter Screen :

The component aids in providing a smooth surface finish for materials during processing.

The filter screen is made using wire mesh with a fine surface that can sieve the materials properly.

Leakage causes during material processing can be avoided using this component.

It is available in different sizes, and this depends on the machine design.

Wire Mesh Screen Ring :

This is the part where the wire mesh is attached it has a glue that supports the bonding of the mesh to the ring.

This bonding makes the mesh to last longer and helps it remain intact during material processing even with high-intensity vibration.

Oversize Material Outlet :

It can also be called an oversize material chute which discharged the large ingredients after the sieving process is completed.

It is located on the upper part of the device to allow easy and quick discharge of these large particles.

Screen Material Outlet :

This is the opposite of the Over-sized material outlet and it is the outlet for all graded, screened products from the machine.

It is located in the lowest part of the machine which allows easy collection of screened ingredients and quick discharge out of the machine.

Springs :

Springs ensure the machine has a hydraulic movement.

The springs also hold the upper part of the machine as it vibrates and processes the materials.

It’s the springs that allow this device to vibrate freely and prevents the vibration from reaching the floor.

Control Panel :

It has many buttons that are used to send signals to the machine about certain actions it should undertake and control panel displayed all the configured operations.

Motor :

The machine uses electricity, and therefore, it’s this component that converts electricity to the energy that runs the machine.

Multiple plane vibration motion by the motor generates more power, which increases the ingredient particle passing rate through sieves.

The motor size of a Vibro sifting machine may be different because of the machine size, production capacity, and design.

Refer the Calibration of Sieve and Screen https://pharmaceuticalupdates.com/2019/02/08/calibration-procedure-for-sieves-and-screens/

Refer Static charges in Manufacturing https://pharmaceuticalupdates.com/2020/03/28/static-charges-in-pharmaceuticals-manufacturing/

Very efficiently written story. It will be valuable to anybody who employess it, as well as yours truly :). Keep doing what you are doing – can’r wait to read more posts.

LikeLike

Great post. I was checking continuously this weblog and I’m impressed! Extremely useful information particularly the final section 🙂 I handle such information much. I used to be seeking this certain info for a long time. Thank you and best of luck.

LikeLike